In regard to small batch manufacturing, there are mainly two ways: CNC machining processing and Vacuum Casting production. CNC machining can process plastic and metal material. Vacuum casting is mainly used for producing plastic prototypes and rubber prototypes, such as ABS-like casted prototypes, Nylon-like cast prototypes, PC-like cast prototypes, rubber-like cast prototypes, etc. Each silicone mold can replicate small batches of parts in around 15-20 pieces of high-quality parts. The vacuum casting prototype is one piece forming, the manufacturing cycle is short and the cost is low. But the accuracy is only around +-0.15mm. Besides, it can't produce small metal parts. For more precision and material requirements, sometimes it is better to choose small-batch CNC machining processing.

Small-Batch CNC Machining Processing Has Become The Primary Processing Method Of Low-Volume Production

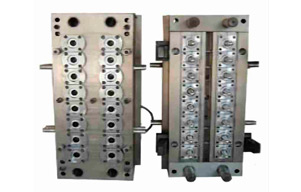

Small batch CNC machining is a traditional processing method that cuts off excess material in the workpiece by the cutting method. In the prototyping industry, small batch CNC machining is generally aimed at large workpieces and appearance versions and precision parts. There is a wide range of materials for Small batch CNC machining including ABS, PMMA, POM, PC, PA, PP, PU, acrylic, aluminum, steel, brass, copper, carbon steel, and many others. Small batch CNC machining parts are low cost, and the processing materials have the advantages of high strength, temperature resistance, high toughness, transparency, etc. At the same time, it can machine small batch machining parts in metal, such as small batch aluminum parts, small batch stainless steel parts, etc. Moreover, the surface treatment forms of small batch CNC machining parts are diversified, such as grinding, sandblasting, painting, Polishing, silk screen printing, electroplating, etc., and the effect can be compared with the products produced by the mold in appearance, assembly, and functional verification, the customer's most design intentions can be achieved. Small-batch CNC machining is quite different from CNC machining steel molds. Small batch CNC machining process is to make a workpiece that can truly reflect the customer's design intentions, while CNC machining steel molds are mainly processed the front mildew and the back mold, and the process is complicated and cumbersome. Small batch CNC machining processing is often used for prototypes of mobile phones, digital cameras, small household appliances and computers, and can also produce large and complex product functional test standard parts, such as air conditioners, television, electronic organs, monitors, audio, medical equipment, motorcycles, Auto parts, and other products.

Custom-made Small Batch CNC Machining Parts

YS Rapid has over ten years of experience in CNC machining service for a wide range industry, such as automation, medical product, automotive, food, aerospace, and many other industries. Feel comfortable to contact us for your small and large batch CNC machining services, we are your right choice to get the highest quality products at the favorable price.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw