How Does Stainless Steel Sheet Metal Fabrication Work?

1. In addition to strict requirements in the production process, the quality of stainless steel sheet metal processing parts requires quality inspection independent of production. One is to strictly control the size according to the drawings, and the other is to strictly control the appearance quality.

2. In daily production and processing, the division of labor and operation of stainless steel sheet metal processing requires a clear method. Different blanking methods are selected according to the expansion diagram and quantity. The sheet metal processing methods include laser cutting, CNC punching machine, Sheet metal shearing, sheet metal molds and other methods, the main steps of stainless steel sheet metal processing are:

1. Blanking. Select blanking. After completion, enter the next process. Different stainless steel workpieces enter the corresponding process according to the processing requirements;

2. Bending. Bending should be based on the scale on the drawing and the thickness of the stainless steel material to determine the tool and sipe used for bending. Preventing the product from colliding with the tool and causing deformation is the key to the selection of the upper die (in the same product , different types of upper molds may be used), the selection of the lower mold is determined according to the thickness of the plate;

3. Welding. In order to make the welding firm, put bumps on the workpiece to be welded, so that the bumps can evenly touch the plate before energized welding, so as to ensure that the heating of each point is consistent, and at the same time, the welding position can also be determined. For sheet metal fabrication welding, it is necessary to adjust the preload time, pressure holding time, hold time, and rest time to ensure that the workpiece can be spot welded firmly; welding includes argon arc welding, spot welding, carbon dioxide maintenance welding, manual arc welding, etc. Spot welding must first consider For the position of workpiece welding, consider positioning tooling to ensure accurate spot welding position during mass production of stainless steel sheet metal.

4. Riveting. When riveting, you should consider the height of the stud and choose a different mold, and then adjust the pressure of the press to ensure that the stud and the workpiece surface are even, and prevent the stud from being pressed firmly or pressed out beyond Workpiece surface, forming the workpiece as invalid.

Stainless Steel Materials Commonly Used in Sheet Metal Fabrication

1. 304 stainless steel.

304 stainless steel is one of the most widely used austenitic stainless steels. It is suitable for sheet metal fabrication of various containers, structural parts, various equipment bodies, etc. It is also possible to manufacture non-magnetic / low temperature equipment and parts.

2. 316 stainless steel.

The addition of molybdenum to 10Cr18Ni12 steel makes the stainless steel more resistant to reducing media and pitting. In seawater and various other media, 316 stainless steel has better corrosion resistance than 304 stainless steel, and 316 stainless steel sheet metal parts are suitable for corrosion resistant products.

3. 317 stainless steel.

The corrosion and creep resistance of 317 stainless steel is better than that of 316L stainless steel. It is used in sheet metal fabrication of petrochemicals, and organic acid corrosion resistant equipment.

4. 321 stainless steel.

It is Titanium stabilized austenitic stainless steel. The addition of titanium improves intergranular corrosion resistance and provides good mechanical properties at high temperatures. Can be replaced with ultra-low carbon austenitic stainless steel. General use is not recommended except for special cases such as high temperature and hydrogen corrosion resistance.

5. 347 stainless steel.

It belongs to niobium stabilized austenitic stainless steel, and niobium is added to improve intergranular corrosion resistance. Corrosion resistance to acids, alkalis, salts and other corrosive media is the same as 321 stainless steel. It has good weldability and can be used as a corrosion-resistant material and heat-resistant steel. It is mainly used for sheet metal manufacturing of thermal power products and petrochemical products, such as containers, pipes, heat exchangers, shafts, industrial furnace furnace tubes, furnace tube thermometers, etc.

6. 440C stainless steel.

It belongs to martensitic stainless steel and has a hardness of HRC57, which is the highest hardness among quenched stainless steels and stainless steels. Mainly used for manufacturing nozzles, bearings, valve cores, valve seats, sleeves, valve stems, etc.

7. 17-4PH stainless steel.

It belongs to martensitic precipitation hardening stainless steel with hardness HRC44. It has high strength, hardness and corrosion resistance and cannot be used at high temperatures above 300°C. It has good corrosion resistance to air and dilute acids or salts. Its corrosion resistance is the same as 304 and 430 stainless steels. Used to manufacture offshore platforms, turbine blades, valve cores, valve seats, sleeves and valve stems. etc.

Advantages of Stainless Steel in Sheet Metal Manufacturing

Stainless steel sheet metal has excellent corrosion resistance and is more durable than ordinary steel sheet metal;

The stainless steel sheet metal has high strength and stable quality;

Stainless steel sheet metal has excellent high temperature oxidation resistance and high strength, so it can resist fire;

The stainless steel sheet metal can realize the diversification of use possibilities;

The stainless steel sheet metal can be processed at room temperature, that is, it is easy to be plastically processed;

Because no many surface treatment is required, the processing and maintenance of stainless steel sheet metal parts is simple;

Stainless steel sheet metal parts have high finish and are easy to clean;

Stainless steel sheet metal has good weldability ;

Stainless steel sheet metal have excellent thermal expansion properties and thermal insulation properties;

YS Rapid Stainless Steel Sheet Metal Fabrication Services – Stainless Steel Sheet Metal Components Manufacturer

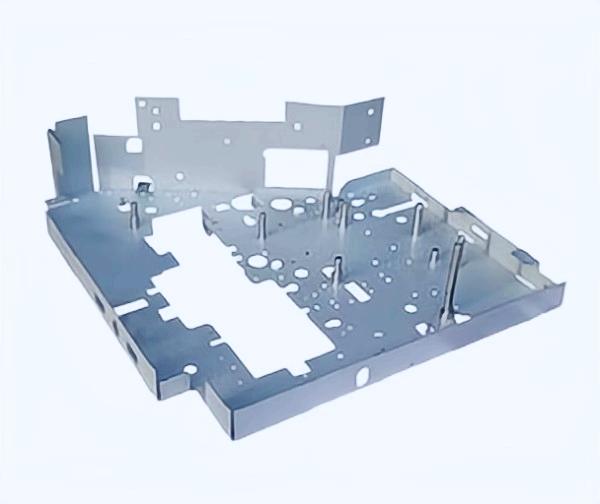

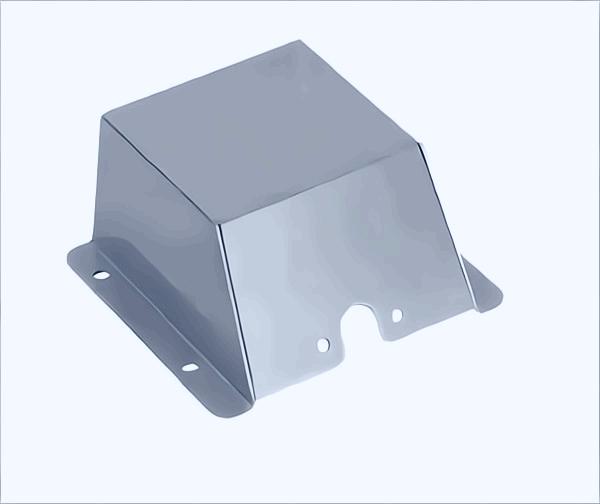

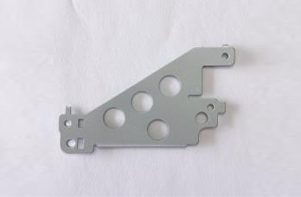

YS Rapid is custom sheet metal fabrication supplier dedicated to the production of high quality stainless steel sheet metal components and products, from very simple stainless steel box frames to complex components and equipment. Using advanced laser cutting, folding and welding techniques, we are able to manufacture complex stainless steel sheet metal components and devices with high precision and minimal distortion.

Why Choose Our Stainless Steel Sheet Metal Fabrication

Competitive price

Strict quality control ensures the quality of your products

Wide variety of stainless steel and other metal sheets for your selection

Small quantities are also welcomed: sheet metal prototypes and sheet metal small volume manufacturing

Customized service, customized according to your drawings, samples or ideas

Rich experience and good technical support ensure that your sheet metal parts are completed on schedule with high quality.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw