Rapid prototyping and small batch manufacturing are two technologies that have revolutionized the manufacturing industry. Rapid prototyping refers to the creation of a physical model of a product using 3D printing technology, while small batch manufacturing is the production of a small quantity of products using CNC machining service or other technologies. Both technologies have opened up new possibilities for manufacturing and have made it easier for companies to bring new products to market quickly. In this article, we will discuss the applications of rapid prototyping and small batch manufacturing in different industries.

Rapid prototyping and small batch manufacturing in automotive industry

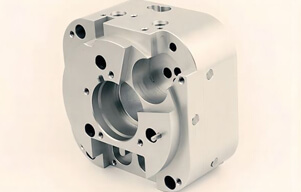

One of the biggest beneficiaries of rapid prototyping and small batch manufacturing is the automotive industry. With the help of rapid prototyping, designers and engineers can quickly create physical models of car components and test their performance. This allows them to identify any issues early on in the design process and make changes as needed. Small batch manufacturing is also used to produce parts for classic cars that are no longer in production. With the help of CNC machining services, these parts can be produced quickly and cost-effectively, allowing car enthusiasts to restore their classic cars to their former glory.

Rapid prototyping and small batch manufacturing in medical industry

The medical industry is another industry that has benefited greatly from rapid prototyping and small batch manufacturing. 3D printing technology has been used to create prosthetics and implants that are customized to the patient's needs. These customized products provide a better fit and higher comfort level for the patient. Small batch manufacturing is also used to produce medical devices and tools that are only needed in small quantities.

Rapid prototyping and small batch manufacturing in aerospace industry

The aerospace industry is another industry that has benefited from rapid prototyping and small batch manufacturing. 3D printing technology has been used to produce lightweight parts that are used in aircraft. These parts are designed to be strong and durable, while also being lightweight to reduce the weight of the aircraft. Small batch manufacturing is also used to produce parts that are needed in small quantities, such as replacement parts for older aircraft.

Rapid prototyping and small batch manufacturing in consumer goods industry

The consumer goods industry has also been impacted by rapid prototyping and small batch manufacturing. With the help of 3D printing technology, designers can quickly create prototypes of new products and test their designs. This allows them to make changes and improvements quickly, reducing the time to market for new products. Small batch manufacturing is also used to produce customized products that are only needed in small quantities, such as personalized phone cases or jewelry.

Rapid prototyping and small batch manufacturing in architecture industry

The architecture industry has also benefited from rapid prototyping and small batch manufacturing. With the help of 3D printing technology, architects can quickly create physical models of their designs. This allows them to get a better sense of how their designs will look and how they will function. Small batch manufacturing is also used to produce customized building components that are only needed in small quantities.

Rapid prototyping and small batch manufacturing have opened up new possibilities for manufacturing and have made it easier for companies to bring new products to market quickly. These technologies have been applied in a variety of industries, including the automotive, medical, aerospace, consumer goods, and architecture industries. With the help of rapid prototyping and small batch manufacturing, designers and engineers can quickly create physical models of their designs and test them for performance, making it easier to identify any issues early on in the design process. Small batch manufacturing is also cost-effective, allowing companies to produce small quantities of customized products quickly and efficiently.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw