Manufacturing methods have evolved significantly over the years, with technology playing a significant role in the changes that we are seeing today. One of the most significant changes in recent times is the rise of rapid prototyping and small batch manufacturing. In this article, we will compare these new manufacturing methods with traditional manufacturing methods, highlighting their benefits and drawbacks.

Rapid Prototyping

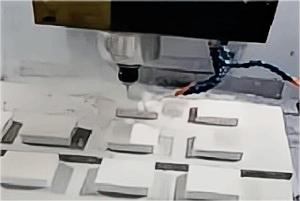

Rapid prototyping is a manufacturing technique that involves the creation of a physical model or prototype of a product using computer-aided design (CAD) software. The prototype is created layer by layer using a variety of materials such as plastic, metal, or ceramic. Rapid prototyping allows for the quick creation of a product prototype without the need for expensive tooling. The prototype can be tested for functionality, design, and durability before full-scale production.

Benefits of Rapid Prototyping

The benefits of rapid prototyping include:

Quick turnaround time: Rapid prototyping allows for the quick creation of a product prototype, which means that the product can be developed and tested much faster than traditional manufacturing methods.

Cost savings: Rapid prototyping eliminates the need for expensive tooling, which can save companies a significant amount of money.

Improved product quality: Rapid prototyping allows for the creation of more accurate product prototypes, which means that the final product will be of a higher quality.

Drawbacks of Rapid Prototyping

The drawbacks of rapid prototyping include:

Limited material selection: Rapid prototyping is limited to a certain range of materials, which may not be suitable for all products.

Limited production quantity: Rapid prototyping is best suited for small production quantities, making it unsuitable for large-scale production.

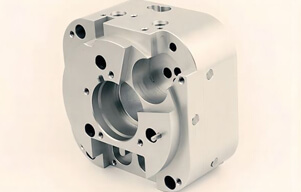

CNC Machining Service

CNC machining service involves the use of computer-controlled machines to create a product from raw material. The raw material is cut or shaped using a variety of tools to create a finished product. CNC machining service is ideal for creating complex parts and components that require a high level of precision.

Benefits of CNC Machining Service

The benefits of CNC machining service include:

High precision: CNC machining service allows for the creation of complex parts and components with a high level of precision.

Wide range of materials: CNC machining service can be used with a wide range of materials, making it suitable for a variety of products.

High production volume: CNC machining service is suitable for large-scale production, making it ideal for companies that require a high volume of products.

Drawbacks of CNC Machining Service

The drawbacks of CNC machining service include:

High cost: CNC machining service is expensive, particularly for small production quantities.

Long lead times: CNC machining service can take a long time to produce a finished product, particularly for complex parts and components.

Comparison with Traditional Manufacturing Methods

Traditional manufacturing methods involve the use of tooling to create a finished product. The tooling is expensive and time-consuming to create, making it unsuitable for small production quantities. Traditional manufacturing methods are also limited in terms of the complexity of parts and components that can be produced.

When compared to traditional manufacturing methods, rapid prototyping and CNC machining service offer several benefits. These new manufacturing methods are faster, less expensive, and can produce more accurate and complex parts and components.

However, these new manufacturing methods also have their drawbacks. Rapid prototyping is limited in terms of material selection and production quantity, while CNC machining service is expensive and has long lead times.

In conclusion, while rapid prototyping and CNC machining service offer several benefits over traditional manufacturing methods, they are not without their drawbacks. Companies need to carefully consider their production requirements and choose the manufacturing method that best suits their needs, no matter it is rapid prototyping, CNC machining service, or traditional manufacturing.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw