In today's fast-paced world, businesses are always looking for ways to get ahead of their competitors. Rapid prototyping has become an essential part of the product development process as it allows for the creation of physical models of products within hours or days. Rapid prototyping involves a variety of methods, each with its unique advantages and disadvantages. In this article, we will explore some common methods of rapid prototyping for plastic and metal parts.

Stereolithography (SLA)

Stereolithography (SLA) is one of the most commonly used methods of rapid prototyping. It involves the use of a UV laser to cure a liquid resin, creating a solid layer-by-layer model. SLA is particularly useful for producing high-resolution models with complex geometries.

One of the main advantages of SLA is its accuracy. It can produce models with high precision and detail, making it an ideal solution for creating intricate or complex parts. However, the downside of SLA is that it can be expensive and time-consuming compared to other rapid prototyping methods.

Fused deposition modeling (FDM) rapid prototyping

Fused Deposition Modeling (FDM) is another popular rapid prototyping method. It involves the use of a 3D printer to create parts layer-by-layer using thermoplastic filaments. FDM is particularly useful for producing low-cost, high-strength parts with simple geometries.

One of the main advantages of FDM is its low cost. It is an inexpensive method compared to other rapid prototyping methods, making it an ideal solution for small businesses or startups with a limited budget. However, the downside of FDM is that it can produce models with lower accuracy and resolution compared to other methods.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is another commonly used method of rapid prototyping. It involves the use of a laser to sinter a powdered material, creating a solid layer-by-layer model. SLS is particularly useful for producing high-strength, durable parts with complex geometries.

One of the main advantages of SLS is its ability to produce parts with high strength and durability. It is an ideal solution for creating functional parts that require high-strength and durability, such as gears or hinges. However, the downside of SLS is that it can be expensive compared to other rapid prototyping methods.

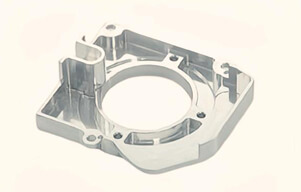

CNC Machining Service

CNC machining service is another popular method used in rapid prototyping. It involves the use of computer-controlled machines to produce parts from raw materials. CNC machining offers several benefits, including high precision and accuracy, and the ability to produce complex geometries.

One of the main advantages of CNC machining is its speed. With CNC machining, parts can be produced quickly and efficiently, making it an ideal solution for rapid prototyping. Additionally, CNC machining allows for easy customization, making it an ideal solution for companies that require unique or custom parts.

Rapid prototyping has become an essential part of the product development process for businesses of all sizes. The ability to create physical models quickly and inexpensively has revolutionized the way companies approach product development. Stereolithography (SLA), Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and CNC machining service are just a few of the many rapid prototyping methods available. Each method has its unique advantages and disadvantages, and businesses must choose the method that best suits their needs. By incorporating rapid prototyping into the product development process, companies can reduce costs, improve time-to-market, and ultimately gain a competitive advantage in their respective industries.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw