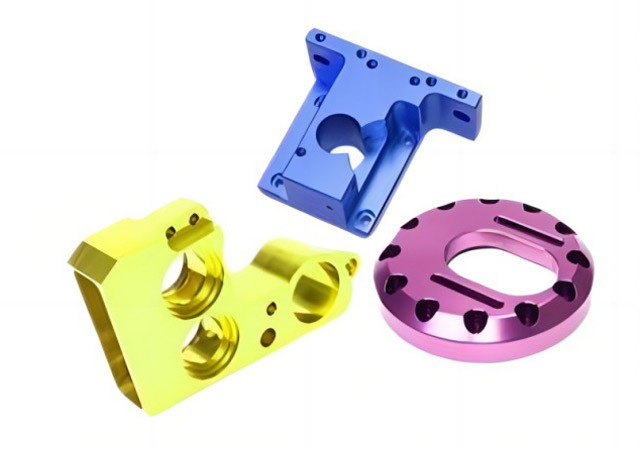

What is CNC Machined Prototype?

A CNC machined prototype is a type of prototype that is created using a CNC machine. A CNC machine is a computer-controlled machine tool that can cut, drill, and shape materials like metal, plastic, wood, and composites.

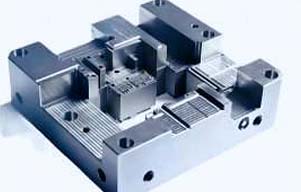

CNC machining is a subtractive manufacturing process, which means that material is removed from a solid block of material to create the desired shape of the prototype. The process starts with a digital 3D model, which is then programmed into the CNC machine using specialized software.

The CNC machine uses various cutting tools, such as drills, end mills, and lathes, to carve the material into the desired shape. The cutting tools are controlled by the computer, which ensures that the prototype is precise and accurate.

CNC machined prototypes can be used to create parts and products for a variety of industries, including aerospace, automotive, medical, and consumer goods. They offer high precision, repeatability, and accuracy, making them an ideal choice for creating functional prototypes and parts for testing and validation purposes.

Ten Reasons to Use CNC for Rapid Prototyping

1. Faster production: CNC machining can manufacture parts quickly, making it ideal for rapid prototyping.

2. Greater precision: CNC machines are capable of machining highly precise and accurate parts, making it possible to produce complex parts with tight tolerances.

3. Wide Range of Materials: CNC machines can work with a wide range of materials, including metals, plastics, and composites, making them ideal for prototyping parts in a variety of industries.

4. Lower costs: CNC machining can be cost-effective for manufacturing small quantities of parts, making it ideal for prototyping and small-batch production runs.

5. Improved design iteration: CNC machines can quickly produce a new part based on a modified design, allowing for rapid iteration and refinement of the design.

6. High Customization: CNC machines can produce highly customized parts based on unique designs, making it possible to create prototypes for specialized applications.

7. Scalability: CNC machining can be easily scaled up for larger production runs if needed, making it a flexible option for prototyping and small-batch production.

8. Consistency: CNC machines can produce parts with consistent quality and accuracy, making it easier to evaluate the performance of a prototype.

9. Reduced waste: CNC machining produces less waste than other manufacturing methods, making it a more sustainable option for rapid prototyping.

10. Improved time to market: By using CNC machining for rapid prototyping, product innovators can get their new products to market faster, giving them a competitive advantage over their competitors.

At YS RAPID, we provide CNC prototyping service to produce rapid prototypes in best quality you could ever hope for. Our strong manufacturing capabilities and rich engineering experience make us capable of bring your product design into custom prototypes in a short time. Contact us today with your CAD file, and you will get an instant quotation in a few hours.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw