The process of making a functional plastic prototype typically involves the following steps:

Design: The first step of making a plastic prototype is to create a 3D design of the part or product. This can be done using computer-aided design (CAD) software.

Material selection: Once the design is complete, the next step is to select the appropriate plastic material for the prototype. This will depend on the specific requirements of the part, including strength, durability, and flexibility.

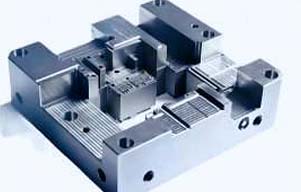

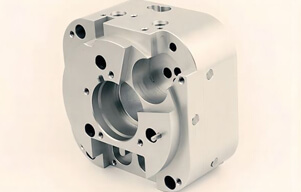

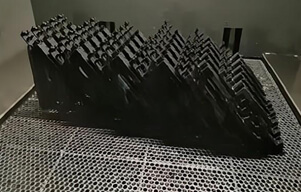

Prototyping technology: There are several prototyping technologies that can be used to create functional plastic prototypes, including additive 3D printing, fast injection molding, and CNC machining, PU casting.

Prototyping process: The prototyping process will vary depending on the chosen technology. For example, with 3D printing, the design is first converted into a 3D printable file, and then the printer builds the part layer by layer using molten plastic. With injection molding, the plastic is melted and injected into a mold to create the part. With CNC machining, the plastic is carved into the desired shape using computer-controlled cutting tools.

Post-processing: Once the prototype is created, it may require post-processing steps such as sanding, polishing, or painting to achieve the desired finish.

Testing: Finally, the functional plastic prototype is tested to ensure that it meets the desired specifications and functions as intended. Any necessary adjustments can then be made before moving forward with production.

YS RAPID is a professional precision machining manufacturer who has rich experience to produce custom precision machining parts in a efficient way. Our professional engineering team has adequate understandings of various technologies to handle different project from diverse customers. Contact YS Rapid today, and let's help you bring your product design into real product.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw