What is CNC Prototype

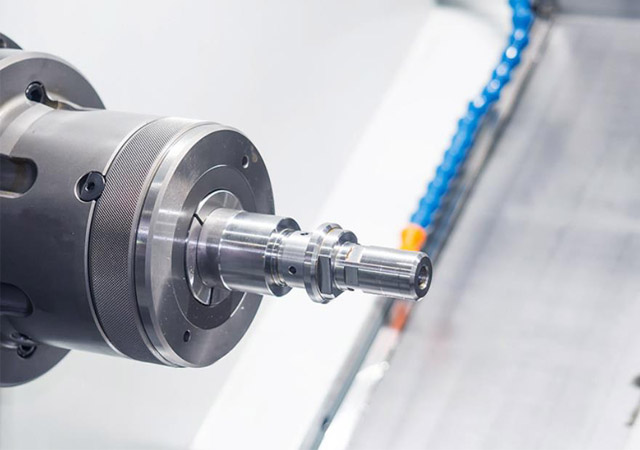

A CNC prototype is a physical object that has been created using the CNC prototyping process. It is a precise replica of a digital design, made by carving a chosen material with a CNC machine.

CNC prototypes are used in the development of new products, allowing designers and engineers to create physical models of their designs for testing and evaluation. These prototypes can be used to check the fit and function of parts, test the strength and durability of materials, and assess the overall design before moving into full-scale production.

CNC prototypes can be made from a variety of materials, including plastics, metals, and wood. The type of material used will depend on the requirements of the design and the intended use of the prototype.

CNC prototyping is a ideal process for creating accurate and functional prototypes quickly and efficiently, enabling designers and engineers to refine their designs and bring their products to market more effectively.

How to Improve the Quality of CNC Prototypes

Here are some tips to improve the quality of CNC prototypes:

Proper Setup: Ensure that the CNC machine is set up correctly before starting the prototyping process. This includes checking the tooling, calibration, and machine parameters.

Material Selection: Choose the right material for the prototyping process. This includes considering the material's strength, hardness, and machinability.

Tool Selection: Select the right tooling for the job. This includes considering the tool's size, shape, and material.

Cutting Parameters: Optimize the cutting parameters, such as speed, feed rate, and depth of cut, to ensure that the machine operates efficiently and produces high-quality parts.

CNC Programming: Ensure that the CNC program is correctly written and optimized for the specific job. This includes considering the tool path, cutting direction, and programming techniques such as tool compensation.

Inspection: Regularly inspect the parts produced during the prototyping process. This includes using measuring tools such as micrometers, calipers, and CMMs to ensure that the parts are within the required tolerances.

Machine Maintenance: Regularly maintain the CNC machine and tooling to ensure that they are operating correctly and producing high-quality parts. This includes cleaning the machine, checking for wear and tear, and replacing any damaged parts.

By following these tips, CNC prototypes manufacturers can improve the quality of their CNC prototyping process, ultimately leading to better parts and increased productivity.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw