Manufacturing high-end CNC prototypes involves several steps that require careful planning, attention to detail, and specialized equipment. Here is a general overview of the process:

Design the prototype: This involves creating a detailed design of the prototype using specialized computer software such as Computer-Aided Design (CAD) or Computer-Aided Manufacturing (CAM). The design should be reviewed and tested to ensure that it meets the required specifications.

Select materials: Choose materials that are appropriate for the prototype's function and design. High-end CNC prototypes typically use high-quality materials that can withstand rigorous testing and provide a realistic representation of the final product.

Prepare the raw material: The raw material, whether it is a block or sheet, must be properly prepared to ensure it is flat, smooth, and clean. This may involve cutting, sanding, or polishing the material.

CNC programming: Use specialized software to create a CNC program that will guide the CNC machine in fabricating the prototype. The program should be designed to ensure that the prototype is manufactured to the required specifications with a high level of accuracy.

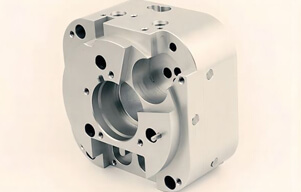

CNC machining: Set up the CNC machine and run the program to fabricate the prototype. The CNC machine will use precision cutting tools to remove material from the raw material block or sheet to create the prototype.

Finishing: Once the CNC machining is complete, the prototype should be finished to remove any sharp edges, burrs, or tool marks. This may involve sanding, polishing, or painting the prototype.

Testing and refinement: Once the prototype is finished, it should be tested to ensure that it meets the required specifications. Any flaws or design issues should be identified and refined until the prototype functions as intended.

Polishing: The final CNC prototype should be polished and refined to provide a high-end appearance that accurately represents the final product.

Overall, the manufacturing process of a high-end CNC prototype requires a combination of technical skills, specialized equipment, and attention to detail to create a prototype that accurately represents the final product.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw