When it comes to rapid prototyping and small batch manufacturing, selecting the right materials is crucial. Choosing the right materials can ensure the success of your project, help you achieve your desired outcome, and save you time and money in the long run. In this article, we'll explore some of the materials suitable for rapid prototyping and small batch manufacturing.

Materials for CNC machining prototyping: plastics

Plastics are a popular choice for rapid prototyping and small batch manufacturing due to their low cost and ease of processing. There are a variety of plastics that can be used, including ABS, PLA, and nylon. Each plastic has its own unique properties and benefits, making it suitable for different applications. For instance, ABS is known for its toughness and durability, while PLA is biodegradable and easy to print.

Rapid prototyping using plastic materials involves using 3D printing technologies, such as FDM or SLA. This allows for a quick turnaround time and easy iteration of designs. Small batch manufacturing using plastics can be done using injection molding, which is a cost-effective and efficient way to produce large quantities of parts.

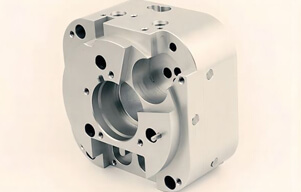

Materials for CNC machining prototyping: metals

Metals are another popular material for rapid prototyping and small batch manufacturing. They offer superior strength and durability, making them suitable for a variety of applications, from aerospace and automotive to medical and consumer products. Popular metals for rapid prototyping and small batch manufacturing include aluminum, stainless steel, and titanium.

CNC machining service is a popular way to produce metal parts for rapid prototyping and small batch manufacturing. It involves using computer-controlled machines to precisely cut and shape the metal into the desired form. This method offers high accuracy, repeatability, and precision, making it ideal for producing complex and intricate parts.

Materials for CNC machining prototyping: composites

Composites are materials made up of two or more distinct materials that combine to form a unique material with enhanced properties. They are becoming increasingly popular for rapid prototyping and small batch manufacturing due to their high strength-to-weight ratio, making them ideal for applications where weight reduction is critical, such as aerospace and automotive.

Composites can be made using a variety of materials, including carbon fiber, fiberglass, and Kevlar. Rapid prototyping using composites involves using 3D printing technologies, such as FDM or SLA, to create the desired shape, followed by curing and post-processing to create the final product. Small batch manufacturing using composites can be done using techniques such as vacuum infusion or compression molding.

In conclusion, selecting the right materials is critical for the success of your rapid prototyping and small batch manufacturing projects. Plastic, metal, and composite materials all offer unique properties and benefits, making them suitable for different applications. By understanding the properties and benefits of each material, you can select the right one for your project and achieve your desired outcome. YS Rapid is a professional rapid prototyping and CNC machining service provider who can guide you selecting the most suitable materials for your project. Contact us today for any of your inquiry.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw