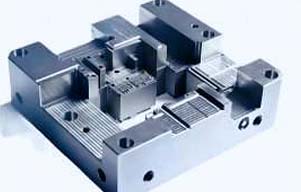

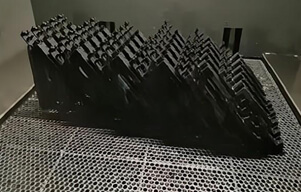

Precision machining services are critical in various industries that require high-quality and complex parts. This manufacturing process involves using advanced equipment and techniques to create parts with tight tolerances and complex shapes. In this article, we will discuss the benefits and applications of precision machining services.

Benefits of Precision Machining Services

High-Quality Parts

Precision machining services can create parts with high accuracy, consistency, and quality. This ensures that the parts meet the required specifications and perform as intended. This high level of precision also reduces the need for rework and maintenance, which can save time and money.

Wide Array of Materials Capablities

Precision machining services can work on a wide range of materials, including metals, plastics, and ceramics. This makes it suitable for various industries such as aerospace, automotive, medical, and electronics. Precision machining services can produce complex and high-precision parts with tight tolerances and intricate designs.

Cost-Effective

Although precision machining services can be expensive, they are cost-effective in the long run because they produce high-quality parts with tight tolerances, reducing the need for rework and maintenance. Precision machining services can also suggest alternative materials or processes to reduce costs while maintaining the quality of the parts.

Applications of Precision Machining Services

Precision machining services have several applications, including:

Aerospace

Precision machining services are critical in the aerospace industry, where parts need to be lightweight, strong, and durable. These parts require tight tolerances and complex shapes to ensure optimal performance.

Automotive

The automotive industry requires high-precision parts that can withstand high temperatures, pressures, and wear and tear. Precision machining services can create parts that meet these requirements and are crucial in the development of engines, transmissions, and other components.

Medical

Medical devices such as surgical instruments, prosthetics, and implants require precision machining to ensure their exact specifications are met. The use of precision machining guarantees that these devices are safe, effective, and compatible with the human body.

Electronics

The production of electronic components such as printed circuit boards, computer chips, and connectors require precise machining to ensure their accuracy and reliability.

In conclusion, precision machining services are crucial for the production of high-quality, reliable, and accurate components used in a wide range of industries.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw