1. High cutting speed and high cutting temperature

Metal materials such as stainless steel have high strength, and the tangential stress and plastic deformation are large during CNC drilling, so the cutting speed is high. In addition, due to the deviation of heat transfer of raw materials, the metal CNC cutting temperature rises, and the high heat is usually concentrated in the slender area near the edge of the CNC blade, which accelerates the damage of the tool.

2. Machining hardening is more serious

Low-alloy steel and some heat-resistant alloy precision parts are austenitic steel, and the hardening tends to increase during CNC drilling, which is generally several times that of carbon steel. The CNC tool drills in the hardened area, resulting in a reduction in the life of the tool.

3. Very easy to stick material

Whether it is low-alloy steel machined parts or martensitic precision parts, they all have the characteristics of tough cutting and very high cutting temperature during machining. When the chips flow past the front of the tool, it will cause a sticky situation and affect the surface roughness of the machined parts.

4. Tool life is shortened

The above metal raw materials generally have high melting point, high plasticity, and high cutting temperature, which shortens the service life of the tool, requires frequent grinding and calibration, which affects production efficiency and increases the maintenance cost of the tool.

Metal precision machining usually requires reducing the angular speed of CNC drilling and cutting tool. Use professional precision parts plate machining or CNC cutting tools of heat-resistant alloys. It is best to use internal cooling for drilling and tapping.

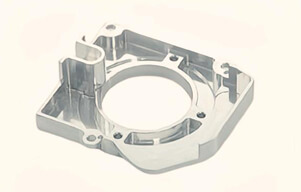

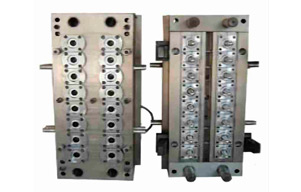

YS Rapid a custom machined parts manufacturer engaged in producing metal cnc machining parts, plastic machined parts, rapid prototypes manufacturing from machining, vacuum casting, silicone molding, 3D printing and so on. If there is anything we can assist you, please contact us freely, our hotline is +8615817251032, email address is: sales@rapid-cncmachining.com

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw