What is Rapid Metal Prototyping Services?

1. In product design & R&D, a prototype is a model or sample of a part, which is made before the mass production start. Prototypes are helpful for designers to test and optimize their product design.

2. Basing on the product’s function & application, Prototypes can be made from a variety of materials, such as plastic, rubber, silicone, metal, etc. Metal prototypes are made from different kinds of metal materials, such as aluminum, stainless steel, brass, bronze, zinc, and many other metal materials.

3. Due to the different structure and features, there are various manufacturing techniques like cnc machining, die casting, sheet metal fabrication, metal extrusion, 3D metal printing, etc.

4. As the metal material used for prototyping is most like the material in mass production, some times metal prototypes is not only used for pre-production prototypes, but also for the prototypes that closely resemble the final parts can be also utilized as end use prototypes.

5. While metal is often used for pre-production prototypes—advanced prototypes that closely resemble final parts—it can also be used for early prototypes for functional assembly and aesthetic look.

Which Rapid Metal Prototyping Method Should You Choose?

When it comes to metal prototyping, choosing the right method can be critical. The choice of metal prototyping method depends on several factors, including the specific requirements of your project, the complexity of the design, desired material properties, budget constraints, and timeline considerations. Here are some commonly used metal prototyping methods along with their key characteristics:

CNC Machining: CNC machining is a versatile metal prototyping method that uses computer-controlled cutting tools to remove material from a solid block of metal, creating the desired shape. It offers high accuracy, tight tolerances, and the ability to work with a wide range of metals. china cnc machining is suitable for both simple and complex designs and provides excellent surface finishes. However, it may not be cost-effective for large-scale production runs.

3D Metal Printing: 3D metal printing, also known as metal additive manufacturing, builds metal parts layer by layer using powdered metal materials. This method allows for complex geometries, internal structures, and customization. It offers design freedom, reduced material waste, and the ability to create intricate parts with high accuracy. 3D metal printing is suitable for low to medium production volumes but may have limitations in terms of material options, size restrictions, and longer production times.

Sheet Metal Fabrication: Sheet metal fabrication involves cutting, bending, and shaping sheet metal to create the desired prototype. It is commonly used for producing parts with thin walls, such as enclosures or brackets. Sheet metal fabrication offers quick turnaround times, cost-effectiveness for certain designs, and the ability to work with a variety of metals. It is suitable for prototypes requiring simple geometries and is often used for low-volume production.

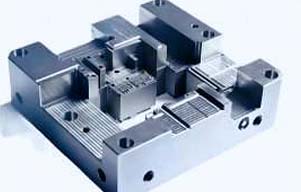

Die Casting: Die casting is a method that uses high-pressure to inject molten metal into a reusable mold, known as a die. It allows for the production of parts with excellent dimensional accuracy, high repeatability, and good surface finishes. Die casting is suitable for producing complex shapes and high-volume production runs. However, the cost of tooling and setup can be higher compared to other methods, making it more suitable for projects with larger production quantities.

When choosing a metal prototyping method, it needs to consider factors such as design complexity, desired material properties, surface finishes, tolerances, production volume, timeline, and budget. YS Rapid is a professional China metal prototyping parts manufacturer who can give you guidance on choosing the most suitable method for your specific project requirements.

Metal Rapid Prototyping Process

The process of metal rapid prototyping involves several steps to quickly create metal prototypes. Here is a general overview of the process:

Material Selection: Choose the appropriate metal material for the prototype based on factors such as mechanical properties, thermal characteristics, and compatibility with the intended application. Consider the specific requirements of the prototype when selecting the material.

Prototype Production: Proceed producing the metal prototype with the selected method, such as CNC machining, sheet metal fabrication,etc. This involves setting up the chosen equipment or machine, loading the appropriate material, and following the specific instructions for that particular method.

Post-Processing: After the metal prototype is produced, perform any necessary post-processing steps to refine the part. This may include removing support structures, sanding or polishing the surface, heat treatment for improved properties, or adding surface finishes and coatings.

Testing and Evaluation: Test and evaluate the metal prototype to assess its functionality, fit, and performance. Conduct thorough testing to identify any design flaws or areas for improvement. Gather feedback from stakeholders and make necessary modifications to the design if required.

YS Rapid's China metal rapid prototyping service allows for the efficient and rapid production of metal prototypes. It enables designers and engineers to validate their designs, make necessary iterations, and ultimately optimize the final product before moving to mass production. If you need custom metal prototyping parts, please don’t hesitate to contact us!

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw