Multiple Use of CNC Rapid Prototyping for New Products Development

CNC rapid prototyping, which involves using custom CNC machining to quickly produce prototypes of new products, has many potential applications for new product development. Here are some of the ways that CNC rapid prototyping can be useful:

Faster time-to-market: CNC rapid prototyping can significantly reduce the time it takes to develop and bring new products to market, allowing companies to stay competitive and meet customer demand.

Cost savings: CNC rapid prototyping can help companies save money on product development by allowing them to identify and address design flaws or issues early in the development process, before committing to expensive tooling or manufacturing processes.

Customization: CNC rapid prototyping can be used to create custom parts or components for new products, allowing for greater flexibility and customization in product design.

Iterative design: CNC rapid prototyping allows for quick and easy iterations of product design, allowing for rapid prototyping and testing of different design concepts.

Small-batch production: CNC rapid prototyping can be used to produce small batches of new products for testing or market research purposes, allowing companies to gauge consumer interest and gather feedback before committing to full-scale production.

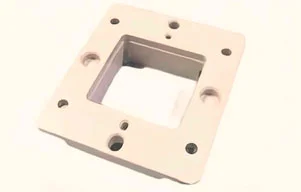

Our professional rapid prototyping services offer a range of high precision, flexible, low cost custom CNC prototyping parts from wide range of plastic and metal materials, helping our customer’s new product launch into market in faster time.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw