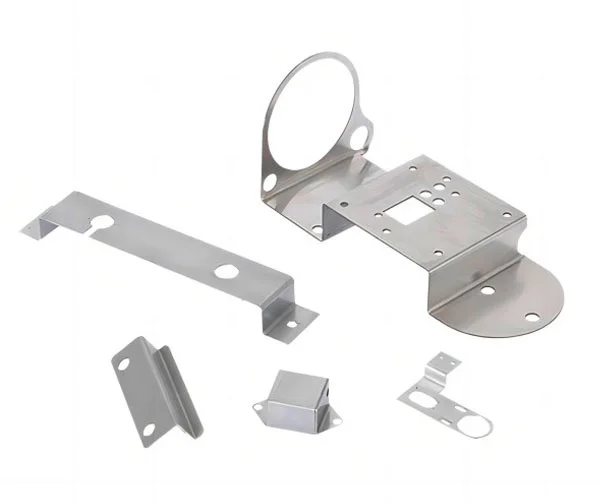

The Techniques of Small Holes Laser Cutting Punching parts Sheet Metal Stamping Fabrication Parts

Precision small holes laser cutting is a specialized process that uses a high-powered laser beam to cut small, intricate holes in various materials. This process is commonly used in China precision machining applications, where precise and accurate cuts are necessary to produce high-quality products.

The laser cutting process uses a focused beam of light to melt and vaporize the material at the point of the cut. This creates a small, precise hole in the material, with minimal damage to the surrounding area. The laser beam can be adjusted to produce holes of various sizes and shapes, depending on the specific application.

Some common materials that can be cut using precision small holes laser cutting include metals such as steel, aluminum, and copper, as well as non-metallic materials such as plastics, ceramics, and composites.

There are several benefits to using precision small holes laser cutting. This process is extremely accurate and precise, allowing for tight tolerances and minimal waste. It is also a fast and efficient process, allowing for high-volume production with minimal downtime. Additionally, laser cutting is a non-contact process, which means that there is no physical contact between the cutting tool and the material, reducing the risk of damage or distortion.

In all, precision small holes laser cutting is a valuable tool in the manufacturing industry, allowing for precise and accurate cuts in a wide range of materials.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw