Precision machining is a crucial process for many industries that require high-quality and complex parts. Choosing the right precision machining manufacturer is essential to ensure that the parts meet the required specifications and are delivered on time. In this article, we will discuss two key factors that OEMs should consider when choosing a precision machining manufacturer: cost and lead time.

Choosing a precision machining manufacturer: cost

Cost is an essential consideration when choosing a precision machining manufacturer. OEMs need to ensure that they are getting the best value for their money without sacrificing quality. Here are some factors that can affect the cost of precision machining services:

Material selection: Different materials have varying costs, and the cost of the material used can significantly affect the overall cost of the project.

Complexity of the part: Complex parts require more time, skill, and equipment to produce, which can increase the cost.

Volume of parts: The larger the volume of parts needed, the lower the unit cost.

Quality control measures: Quality control measures such as inspection and testing can add to the cost of precision machining services but are essential to ensure the quality of the parts.

It is essential to choose a precision machining manufacturer that offers cost-effective solutions without compromising on quality. An experienced manufacturer can suggest alternative materials or processes to reduce costs while maintaining the quality of the parts.

Choosing a precision machining manufacturer: lead time

Lead time is the time it takes for the precision machining manufacturer to complete the project and deliver the parts. Lead time is critical for OEMs as it can impact their time-to-market and overall profitability. Here are some factors that can affect the lead time of precision machining services:

Capacity and availability: The capacity and availability of the precision machining manufacturer can affect the lead time. A manufacturer with a higher capacity and availability can typically deliver parts faster.

Complexity of the part: Complex parts require more time to produce, which can increase the lead time.

Quality control measures: Quality control measures such as inspection and testing can add to the lead time of precision machining services but are essential to ensure the quality of the parts.

It is essential to choose a precision machining manufacturer that can deliver parts on time and within the required lead time. An experienced manufacturer can optimize the design of the parts to reduce the lead time and suggest alternative materials or processes to speed up the production process.

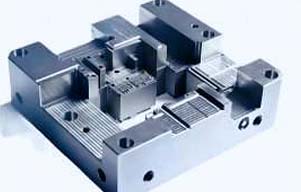

YS RAPID is a precision machining manufacturer that specializes in providing cost-effective and high-quality solutions to their customers. They have a team of experienced engineers and technicians who can handle complex and high-precision parts with tight tolerances. With state-of-the-art equipment and a robust quality control process, YS RAPID can deliver parts that meet the exact specifications of their customers while ensuring a fast turnaround time. Choosing the right precision machining manufacturer like YS RAPID can help OEMs reduce costs, increase their profitability, and get their products to market faster.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw