Nowadays, Robots are everywhere - in movies, airports, food production, hotels, and even in factories. Robots have many different functions and uses, and as they become easier and cheaper to manufacture, they are also becoming more common use in industry. As the demand for robotics increases, robot manufacturers need to keep up with the market, and one basic method of making robotic parts is Customized CNC machining Services. This article will learn more about why Customized CNC machining Services are so important to making robots.

CNC machining Service is tailor-made for robots

Firstly, Customized CNC Machining Service Enables The Production of Parts with Extremely Fast Lead Times

Most of the time, as soon as your 3D model is ready, you can start making components with a CNC machine. This enables rapid iteration of prototypes and rapid delivery of custom cnc machined robotic parts for professional applications.

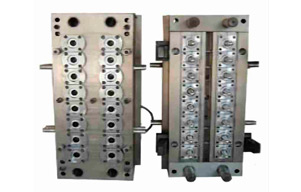

Secondly, Customized CNC Machining Service Is The Ability To Precisely Manufacture Parts To Specification

This manufacturing precision is especially important for robotics manufacturing, as dimensional accuracy is key to making high-performance robots. Precision CNC machining keeps tolerances within +/- 0.0002 inches, and the part allows precise and repeatable movements of the robot.

Thirdly, Surface Finish Is Another Reason To Use CNC Machining Services To Produce Robotic Parts

Interacting parts need to have low friction, and precision CNC machining can produce parts with surface roughness as low as Ra 0.8 μm, or lower through post-processing operations such as polishing. In contrast, die casting (before any finishing) typically produces a surface roughness close to 5µm. Metal 3D printing produces a rougher surface finish.

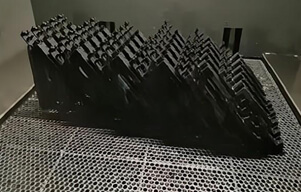

Finally, CNC Machining Materials Are Ideal For The Robot'S Application

Robots need to be able to move and lift objects stably, requiring strong and hard materials. These necessary properties are achieved by certain machining metals and plastics. Additionally, robots are often used for custom manufacturing or low-volume manufacturing, which makes customized CNC machining

Service an ideal way of robotic parts manufacturing.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw